Some workplace injuries, like those caused by accidents or personal error, can’t be avoided. However, most common injuries can be avoided with the right precautions.

Better industrial safety precautions and features are the number one thing that facilities can do to prevent common workplace injuries. Often, these fixes are small and inexpensive but can save workers from painful injuries—and your company from costly worker’s compensation payouts.

Here are some of the smartest steps you can take to improve industrial safety and prevent injuries.

Eliminate Fall Risks

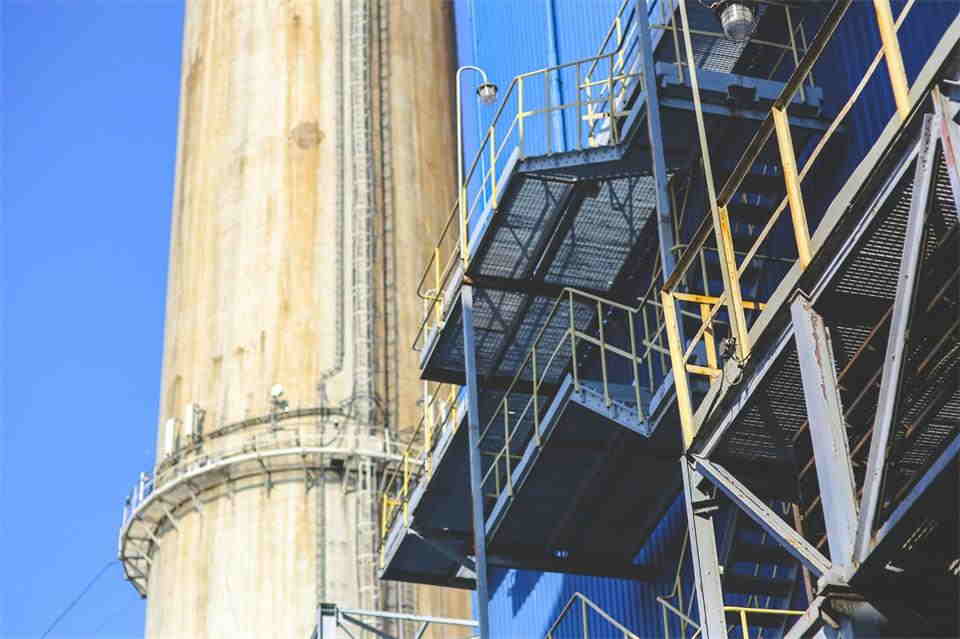

One of the most common sources of workplace injuries is a fall. In industrial settings, workers have to work on elevated platforms or other high areas. Without the right protection, they can easily slip or fall. Depending on the height, a fall may have severe consequences for an employee’s health.

The best way to eliminate fall risks is to secure the edges of elevated areas. Putting up guardrails sets up barriers between platforms and the edge so that even if someone slips, they won’t fall over. Make sure that the guardrails are securely installed so they can withstand heavy weights falling against them and are high enough to block a person from falling.

Safety engineers can help you identify potential fall risks around your facility and eliminate them. Other precautions such as ramps and safety nets can work in tandem with guardrails to limit falls.

Another common source of fall risks is the surface area near an elevated edge. Worker falls are often caused by people slipping on unsafe terrain. Install textured flooring near the edge to make the elevated surface less slippery. Make sure that anything that could make a floor slippery, such as water or cleaning liquids, is not spilled while workers are around.

Make Sure There Is Enough Light

You may not realize it, but adequate lighting is an important feature of industrial safety, not just a design choice. When workers cannot see properly, injuries are more likely to happen, especially if they are working with hazardous equipment that has sharp blades or other components.

With large industrial spaces, it can be difficult to light everything and avoid dark corners. Mapping your facility helps. Go through the entire facility and map shadowy areas that are potentially hazardous. Ensure that your facility is complying with legal requirements for lighting.

Changing the lighting can help improve employee focus as well. Talk to experts about adding additional lighting fixtures or changing the temperature and intensity of your existing lights. When employees are more focused, they are less likely to get injured.

Make Sure That Your Equipment Is Maintained and Up-to-Date

Equipment-related injuries are some of the most common workplace injuries in industrial facilities. Workers can cut themselves, crush fingers, or otherwise get hurt. Factory machinery contains dangerous parts and without the right precautions, injuries can occur.

While some risk is inherent when working with this type of machinery, you can limit the number of machine-related injuries by maintaining your equipment properly. Faulty machinery that jams, skips, or acts in an unpredictable way often causes injuries. Regularly inspect your machines and make small repairs, such as oiling rusty parts, to avoid bigger headaches down the line.

Even if a machine doesn’t malfunction, it can still cause injuries. Most industrial jobs involve repetitive movements that cause strain over time. This leads to injuries such as slipped discs and other back problems, sprains, and muscle strains.

If you have the resources, investing in ergonomic manufacturing processes can help prevent strain-related injuries. Replacing machinery that requires workers to repeat unnatural positions, automating tasks, and giving workers more frequent breaks can reduce the rate of back problems and other injuries.

Institute Cleaning Protocols

Two of the most unlikely tools in your battle against workplace injuries are a broom and a mop. They may not be glamorous, but these pieces of equipment are some of the most important for workplace safety.

That is because regular cleaning and maintenance protocols are crucial to preventing workplace injuries. In industrial facilities, clutter is dangerous. Loose objects lying around are trip hazards that also prevent workers from moving naturally through the facility. Dust, residue, and other debris on the floor are slip hazards that cause falls.

If your facility has been loose with cleaning and maintenance before, now is the time to tighten up procedures. Set up regular cleaning schedules—and check in to make sure they get done. This includes all surfaces in your facility, such as floors, equipment, platforms, and stairs.

As part of your cleaning protocols, conduct a thorough analysis of your facility. Analyze past workplace injuries and the floor plan to identify potentially hazardous areas that need additional attention.

Organize Worker Safety Training

While the equipment in your facility is a major factor in industrial safety, so are the people. Human error is one of the most frequent causes of workplace injuries.

People don’t get injured because they are careless or doing the job poorly. It’s understandable that during a long shift, attention flags. Workers may also forget about important safety precautions as they settle into a routine or do not know how to recognize common hazards.

Regular safety training can help prevent human error. Different training methods can be used to keep safety knowledge fresh and accessible. In-person workshops are great for hands-on learning, but combining them with digital tools – like a learning management system Australia – allows training to be delivered consistently across teams, tracked over time, and reinforced through bite-sized, on-demand content.

Organize workshops within your facility to go over specific aspects of workplace safety, such as fall risks. Make sure that all workers understand your facility’s safety protocols.Once the workshop is over

Once the workshop is over, reinforce that knowledge by designating workplace safety representatives that will remind people. Secure enough protective equipment and make sure that workers use it, especially when performing hazardous tasks.

Changes to Industrial Facilities for Better Workplace Safety

Workplace safety is important for every business working in hazardous fields. Precautions such as better safety training and regular maintenance protocols can reduce workplace injuries and improve productivity.

Physical changes to your facility are also important for improving industrial safety. Replacing faulty and unergonomic equipment and placing physical barriers around risky areas such as elevated platforms can prevent the most severe workplace injuries.

Industrial safety should be a priority for your business, not just because of your bottom line, but also for the overall well-being of your employees.